News

Common Cooling Solutions in IDC : Chapter 1. Air Cooled Direct Evaporative Air Conditioner System

It’s indoor air conditioner to control the temperature and humidity in IDC (Internet Data Center), and the indoor air conditioner has the characteristics of high efficiency, high sensible heat ratio, high reliability and flexibility, which can meet the requirements of increasing server heat dissipation, constant control of humidity, air filtration and other aspects in IDC.

With the stringent requirements of PUE (Power Usage Effectiveness) in different regions and the wide application of high-density servers, there are more and more new cooling solutions, increasingly developed and used in IDC, I’ll introduce the traditional and new cooling solutions in IDC in the forthcoming 7 chapters. Let’s start with Chapter 1 – Air Cooled Direct Evaporative Air Conditioner System.

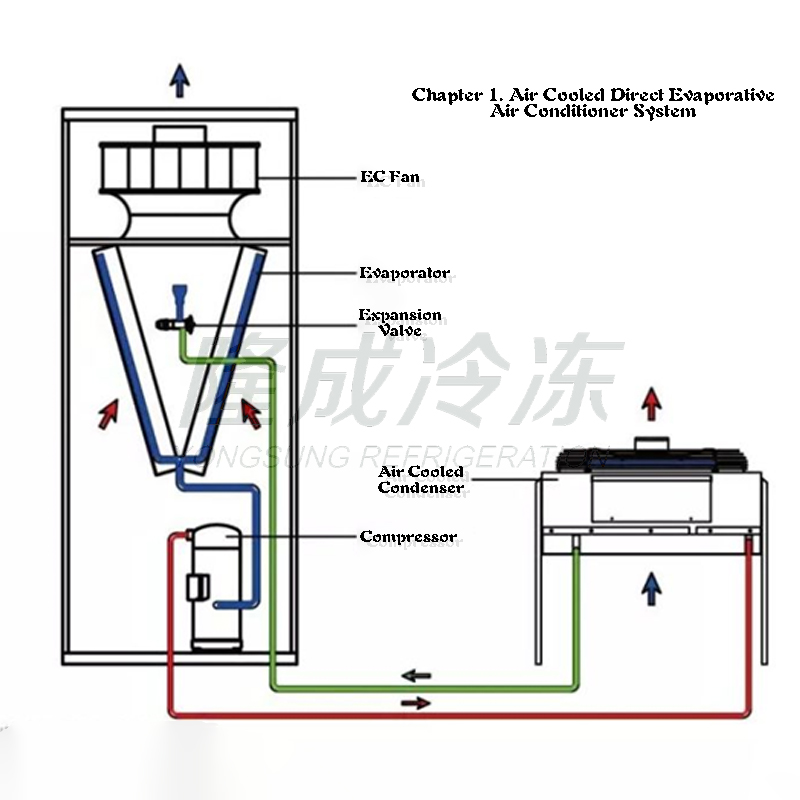

1. Air Cooled Direct Evaporative Air Conditioner System Composition

Air Cooled Direct Evaporative Air Conditioner System is mainly composed of frame, compressor, evaporator, condenser, electronic valve, indoor fan, outdoor fan, unit control system, temperature and humidity sensor, etc.

The condenser is outdoor fin heat exchanger, and the evaporator is indoor fin heat exchanger. After the refrigerant high temperature gas discharged from the compressor is condensed into liquid in condenser, it’s throttled and depressurized by the expansion valve to become low temperature gas-liquid mixture, and then flows into the evaporator absorbing heat and evaporating, and it returns to the compressor to complete a refrigeration cycle. At the same time, the air in the room is cooled by passing through the evaporator and the cold air is sent to the room by indoor fan.

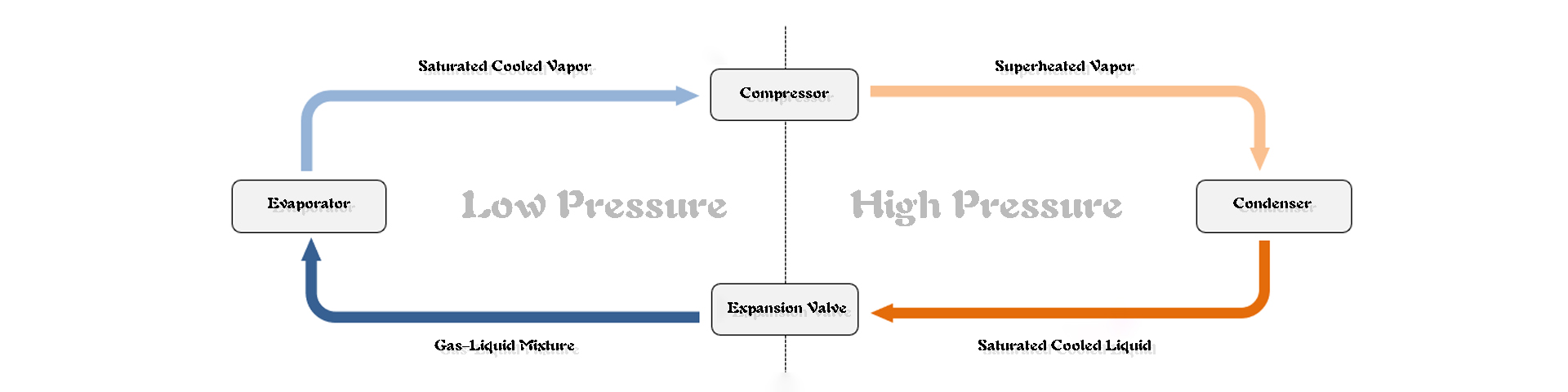

2. Vapor Compression Refrigeration System Scheme Diagram

The low-pressure and low-temperature refrigerant vapor flowing from the evaporator is sucked by the compressor, and is compressed into high-pressure and high-temperature vapor and discharged by the compressor. Thus, the refrigerant vapor is divided into high-pressure region and low-pressure region.

High-pressure region is from the discharge port of compressor to the inlet of the expansion valve, in which the pressure is as known as high pressure or condensing pressure, and the temperature is as known as condensing temperature.

While low-pressure region is from the outlet of expansion valve to the suction port of the compressor, in which the pressure is as known as low pressure or evaporating pressure, and the temperature is as known as evaporating temperature.

It’s the pressure difference between the high-pressure region and low-pressure region caused by the compressor that makes the refrigerant flow continuously in the system. Once the pressure difference disappears, which is one of the high and low pressure balances, the refrigerant stops flowing. It’s totally due to the compressor compressing vapor that makes the generation and value of high and low pressure difference, and the continuous operation of the compressor is realized by consuming electric or mechanical energy.

There are 4 processes for vapor compression refrigeration system, shown in the picture as below:

2.1 Evaporating Process

After the refrigerant liquid flows into the evaporator through the expansion valve, it begins to boil and vaporize due to the decrease of pressure. So the vaporization/evaporating temperature is related to the pressure.

In the process of vaporization, the refrigerant liquid absorbs the heat of surrounding medium, including water, air or articles, and the temperature of these media decrease and achieve the refrigeration purpose.

The vaporization of the refrigerant liquid is a gradual process, and finally all the refrigerant liquid become dry saturated vapor and then flow into the suction port of the compressor.

2.2 Compressing Process

In order to maintain a certain evaporating temperature, the refrigerant vapor must continuously flow out from the evaporator. The refrigerant vapor from the evaporator is sucked in the compressor and compressed into high-pressure gas. In addition, the compressor consumes a certain amount of mechanical energy during the compressing process, and the mechanical energy is converted into heat energy in this process. Therefore, the temperature of the refrigerant vapor is increased and the refrigerant vapor is overheated.

2.3 Condensing Process

The high-pressure refrigerant vapor discharged from the compressor will release heat in the condenser and transfer the heat to the surrounding medium - water or air, so that the refrigerant vapor gradually condenses into liquid.

In the condenser, there are two basic conditions for the refrigerant vapor to release heat to the medium: first, the condensing temperature of the refrigerant vapor must be higher than the temperature of the surrounding medium, and an appropriate temperature difference shall remain; Second, according to the amount of refrigerant vapor sent into the condenser by the compressor, the condenser should have appropriate pipe length and area to ensure that the refrigerant vapor can be fully condensed in the condenser.

2.4 Expansion Process

The refrigerant liquid from the condenser is decompressed to the evaporating pressure by expansion valve for example. The refrigerant temperature after throttled also decreases to the evaporating temperature. And the gas-liquid mixture go into evaporator for evaporating process.

3. Applications

(1) Compared with the Chilled Water Central Air Conditioner System, Air Cooled Direct Evaporative Air Conditioner System has a more simple structure and eliminates the cooling tower, water pump, supporting pipes, and etc.

(2) It’s applicable to the areas where it’s short of water and without cooling water system.

(3) For IDC with similar scale, the operating cost of Air Cooled Direct Evaporative Air Conditioner System is high.

(4) In China, most of the large IDC adopt the combination of chilled water system, chiller, heat exchanger, chilled pump, cooling pump, chilled tower and etc. in the recent years.

(5) In USA, more and more IDCs use dry coolers and immersion cooling solutions in replace of the traditional cooling systems.