Products

Featured Products

- Steel band

- 100~5000Kg/h

- 1200mm/1500mm

- Freon, Ammonia, CO2

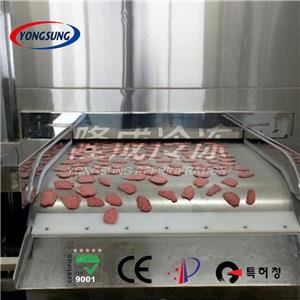

Solid Belt Tunnel Freezer can freeze: whole fish, cod, catfish, basa fish, tuna, salmon, fish fillet, etc.

We do custom design for all our customers worldwide, and have many installations in Korea, China, USA, South East Asia and etc

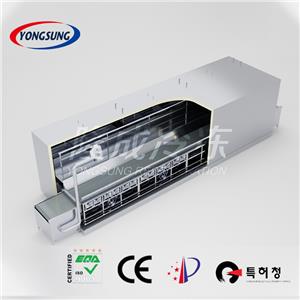

Overview

Dalian Yongsung Refrigeration dose custom design and manufactures solid belt tunnel freezer according to the actual needs of every customer. Use food grade SUS304 solid belt with 1200/1500mm belt width as option, to meet the requirements of different products, freezing capacity and reserved space for installation. Different materials for fins and tubes of evaporator can apply to different operation environment. And all the parts direct contact with frozen products are made of food grade SUS304. The solid belt tunnel freezer is mainly applicable to the quick freezing of flat food, mainly used in the aquatic industry, such as fish fillets, shrimp, abalone, etc.

Features

● Superior thermal conductivity shortens quick freezing time;

● Compared with mesh belt freezer, it’s impossible for smaller size products to block the mesh belt or fall from the mesh hole;

● There will be no foreign matters between the belts, which guarantees the hygiene;

● The products will not have the mark of the belt;

● Can clean the solid belt while the freezer is running;

● Built in inventor and PLC automatic control system;

● Use steam coil to defrost with a small amount of water; (optional)

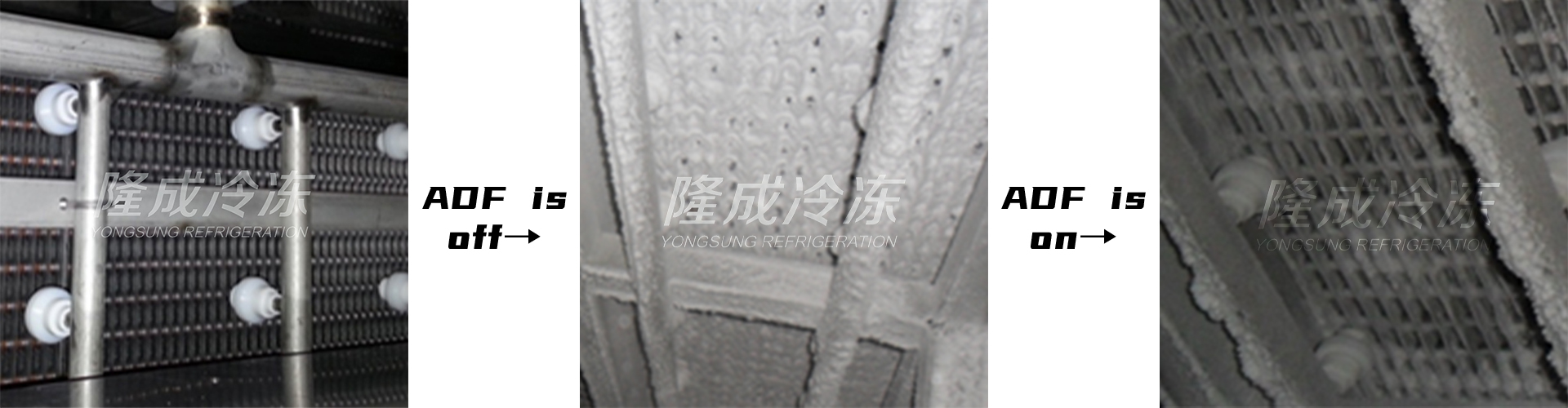

● Use ADF device to extend defrosting period; (optional)

● Uses CIP system - Belt and Chamber cleaning are convenient. (optional)

Specifications

Freezing capacity | 100~5000Kg/h |

Belt material | Food grade SUS304 |

Belt width | 1200mm/1500mm |

Evaporator | Aluminum/stainless steel tubes, aluminum/aluminum-magnesium alloy fins, variable pitch |

Refrigerant | Freon, Ammonia, CO2 |

Defrosting | Water/ADF (optional) |

Options

ADF device

Slow down the frost accumulation time to make the freezer work for longer continuous time.

Reduce defrosting times and defrosting water cons-umption to save the cost of defrosting water and sewage treatment.

CIP system

Clean and disinfect the interior of the freezer.

Applications

Partners