Products

Featured Products

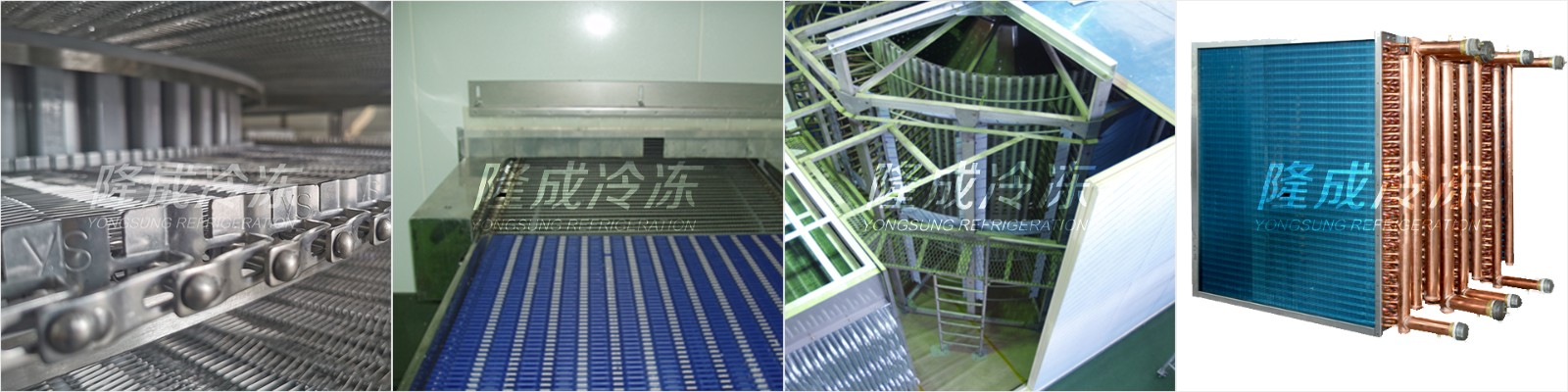

- Single Drum/ Double Drum

- 100~5000Kg/h

- 450~1067mm

- 2~40 tiers

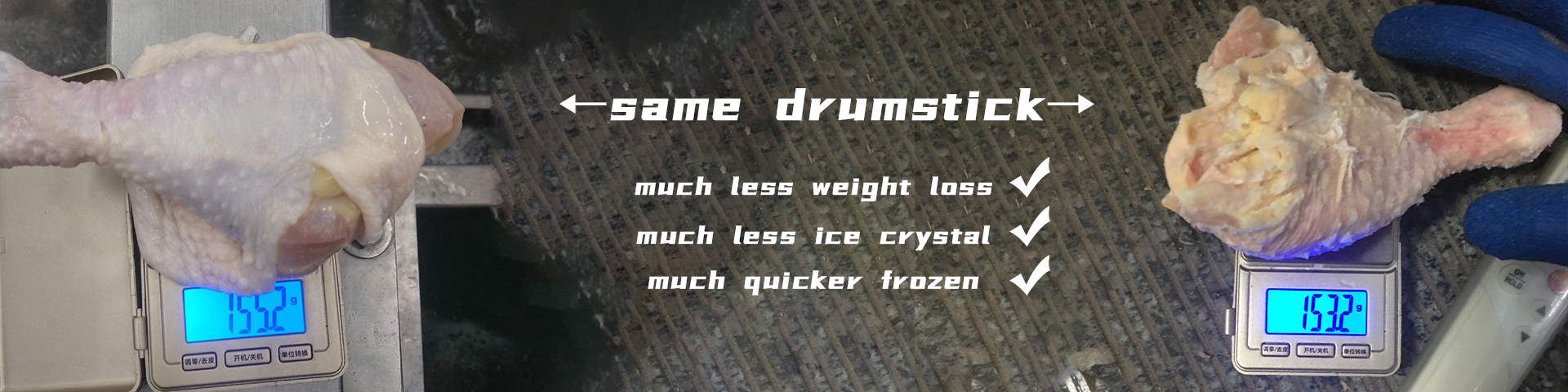

It can freeze items such as chicken, chicken wings, wing drumettes, wing mid-joints, wing tips, chicken legs, thighs, drumsticks, breasts, breast fillets, and white meat.

We offer custom designs for all our customers worldwide and have numerous installations in Korea, China, the USA, Southeast Asia, and other regions.

Overview

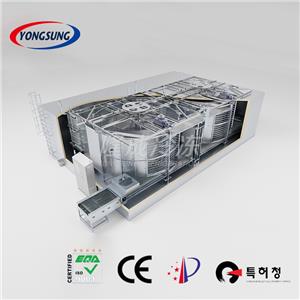

At Dalian Yongsung Refrigeration, we offer bespoke low-tension single/double drum spiral freezers designed to meet the unique needs of each customer. Our freezers come in multiple sizes for mesh belt width and cage diameter, accommodating different product requirements, freezing capacities, and installation spaces. We use various materials for the evaporator's fins and tubes to match different operational environments. All components in direct contact with frozen products are made from food-grade SUS304. Perfect for individually quick freezing small foods or large items such as whole chickens, whole fish, and prepared meals, our spiral freezers ensure quality and efficiency.

Different materials for fins and tubes of evaporator can apply to different operation environment. And all the parts direct contact with frozen products are made of food grade SUS304.

Spiral freezer is applicable to individual quick frozen of small-piece food as well as large-sized frozen food such as whole chicken, whole fish, prepared meals, etc.

Features

Space-Efficient: Requires smaller floor space compared to tunnel freezers.

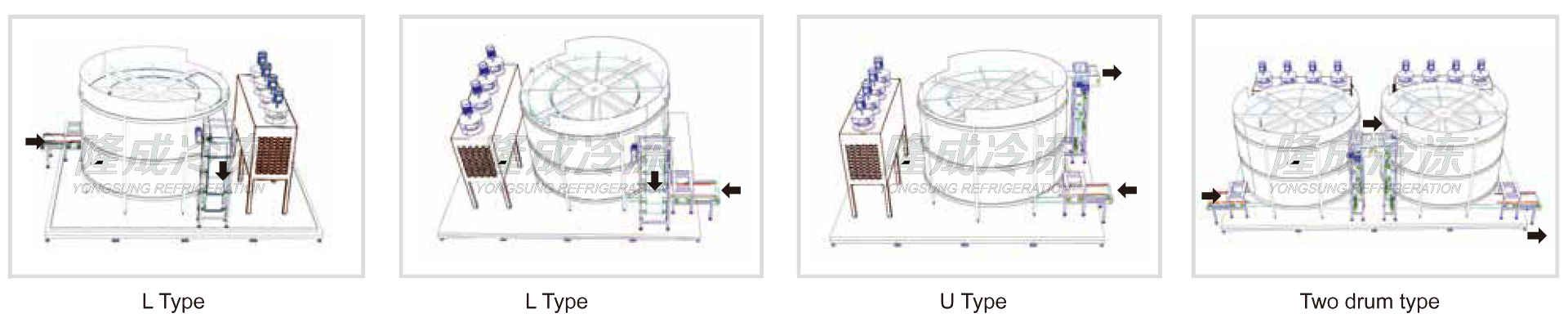

Flexible Design: Offers versatile input and output directions (Straight, L-type, U-type).

Modular and Compact: Features a unit modular and compact design.

Hygienic and Safe: Reducer and fan motor are installed outside the freezer chamber to prevent food contamination and reduce freezing load by removing motor-generated heat, ensuring hygiene and energy efficiency.

High-Performance Fan: Utilizes a centrifugal fan with high static pressure to minimize frosting and extend operation time.

Advanced Control: Equipped with a built-in inverter and PLC automatic control system.

Optional Features:

Steam Coil Defrost: Uses a small amount of water for defrosting.

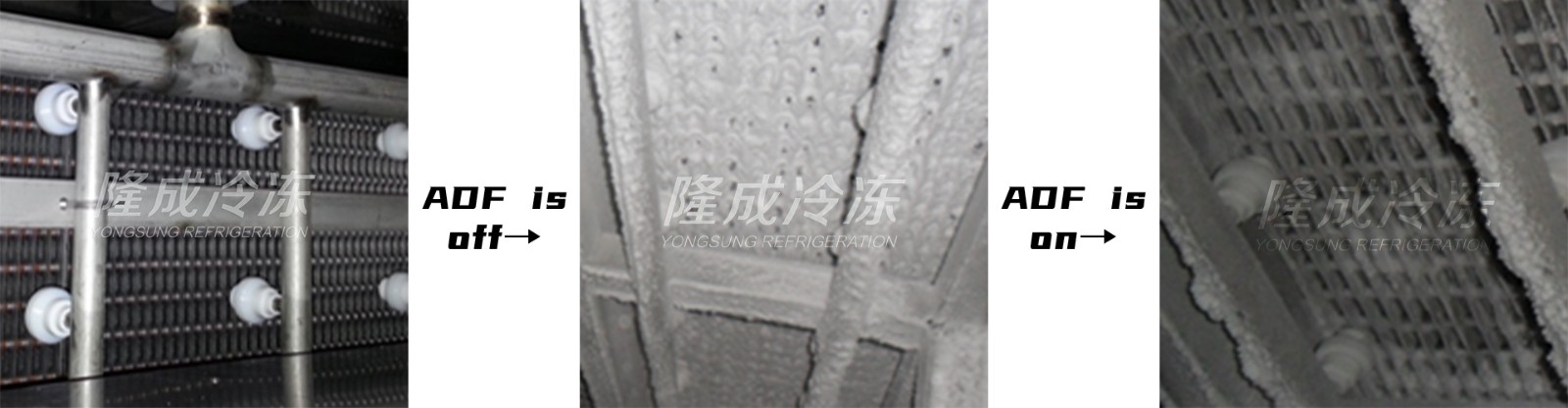

ADF Device: Extends the defrosting period.

CIP System: Facilitates convenient belt and chamber cleaning.

Specifications

Structure | Single drum/ double drum |

Inlet/outlet direction | Straight, L type, U type |

Freezing capacity | 100~5000Kg/h |

Belt material | Food grade SUS304/modular plastic belt |

Belt width | 450~1067mm |

Cage diameter | 1500~4500mm |

Tiers | 2~40 tiers |

Evaporator | Aluminum/stainless steel tubes, aluminum/aluminum-magnesium alloy fins, variable pitch |

Refrigerant | Freon, Ammonia, CO2 |

Defrosting | Water/ADF (optional) |

Options

ADF device

Slow down the frost accumulation time to make the freezer work for longer continuous time.

Reduce defrosting times and defrosting water cons-umption to save the cost of defrosting water and sewage treatment.

CIP system

Clean and disinfect the interior of the freezer.

Applications

|

|

|

|

Partners