Products

Featured Products

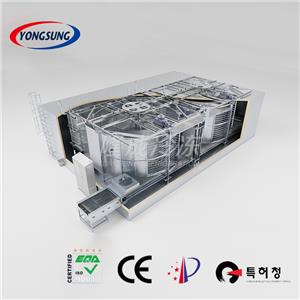

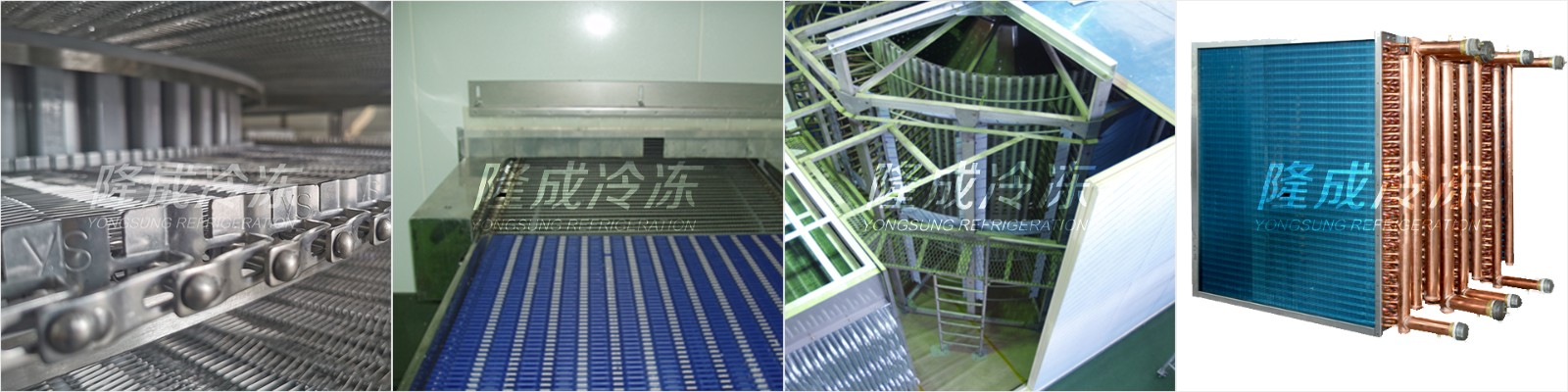

- Single Drum/ Double Drum

- 100~5000Kg/h

- 450~1067mm

- 2~40 tiers

Capable of freezing: whole fish, cod, catfish, basa fish, tuna, salmon, shells, molluscs, clam, scallop, conch, octopus, squid, lobster, prawn, shrimp, sea cucumber, etc.

Overview

Dalian Yongsung Refrigeration custom designs and manufactures low-tension single/double drum spiral freezers to meet the specific needs of every customer. Our freezers offer different sizes for mesh belt width and cage diameter, addressing various product requirements, freezing capacities, and installation spaces. We utilize different materials for the evaporator's fins and tubes to suit diverse operational environments. All parts in direct contact with frozen products are constructed from food-grade SUS304. Suitable for individually quick freezing small-piece foods and large-sized items like whole chickens, whole fish, and prepared meals, our spiral freezers deliver optimal performance.

Features

Requires less floor space compared to tunnel freezers

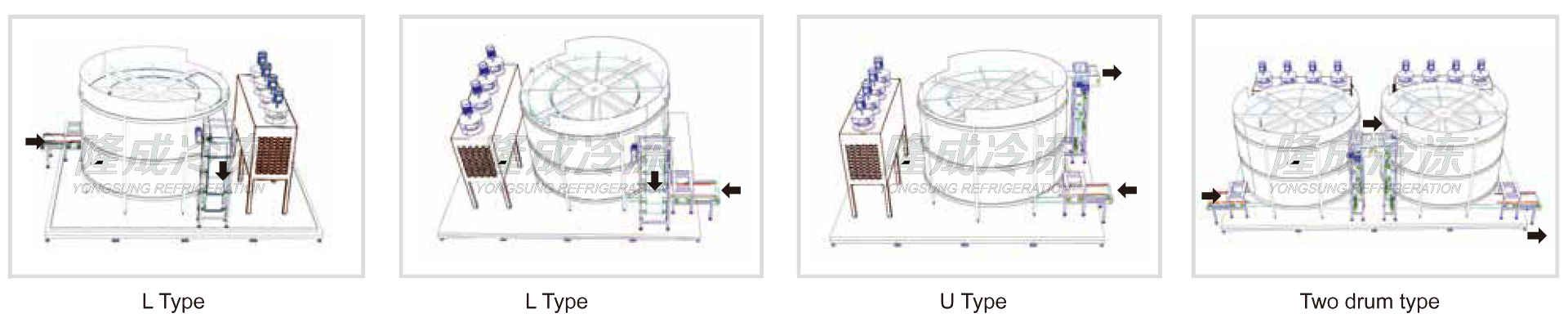

Flexible input and output design options (Straight, L-type, U-type)

Modular and compact unit design

External installation of reducer and fan motor to prevent food contamination and reduce freezing load, ensuring hygienic, safe, and energy-saving operation

High static pressure centrifugal fan for reduced frosting and extended operation time

Built-in inverter and PLC automatic control system

Optional steam coil for defrosting with minimal water usage

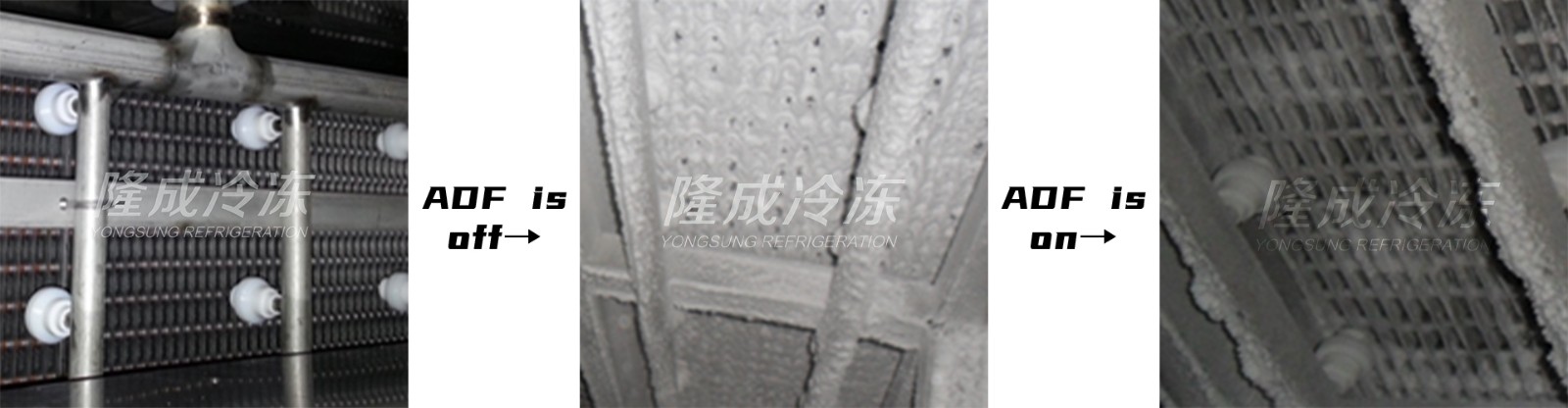

Optional ADF device to extend defrosting periods

Optional CIP system for convenient belt and chamber cleaning

Applications:

Individual quick freezing of small-piece foods

Freezing large-sized foods such as whole chicken, whole fish, and prepared meals

Materials:

Food grade SUS304 for all parts in direct contact with frozen products

Various materials for evaporator fins and tubes to suit different operational environments

Custom Design:

Tailored to meet specific customer needs

Different sizes available for mesh belt width and cage diameter to accommodate various products, freezing capacities, and installation spaces

Specifications

| Structure | Single durm/ double drum |

| Inlet/outlet direction | Straight, L type, U type |

| Freezing capacity | 100~5000Kg/h |

| Belt material | Food grade SUS304/modular plastic belt |

| Belt width | 450~1067mm |

| Cage diameter | 1500~4500mm |

| Tiers | 2~40 tiers |

| Evaporator | Aluminum/stainless steel tubes, aluminum/aluminum-magnesium alloy fins, variable pitch |

| Refrigerant | Freon, Ammonia, CO2 |

| Defrosting | Water/ADF (optional) |

Options

ADF device

Slow down the frost accumulation time to make the freezer work for longer continuous time.

Reduce defrosting times and defrosting water cons-umption to save the cost of defrosting water and sewage treatment.

CIP system

Clean and disinfect the interior of the freezer.

Applications

Partners